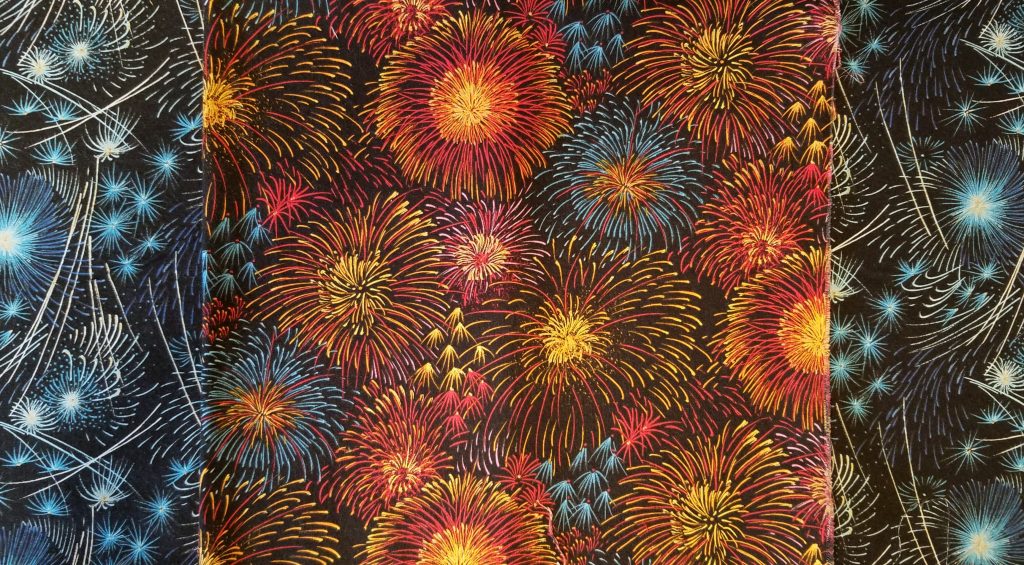

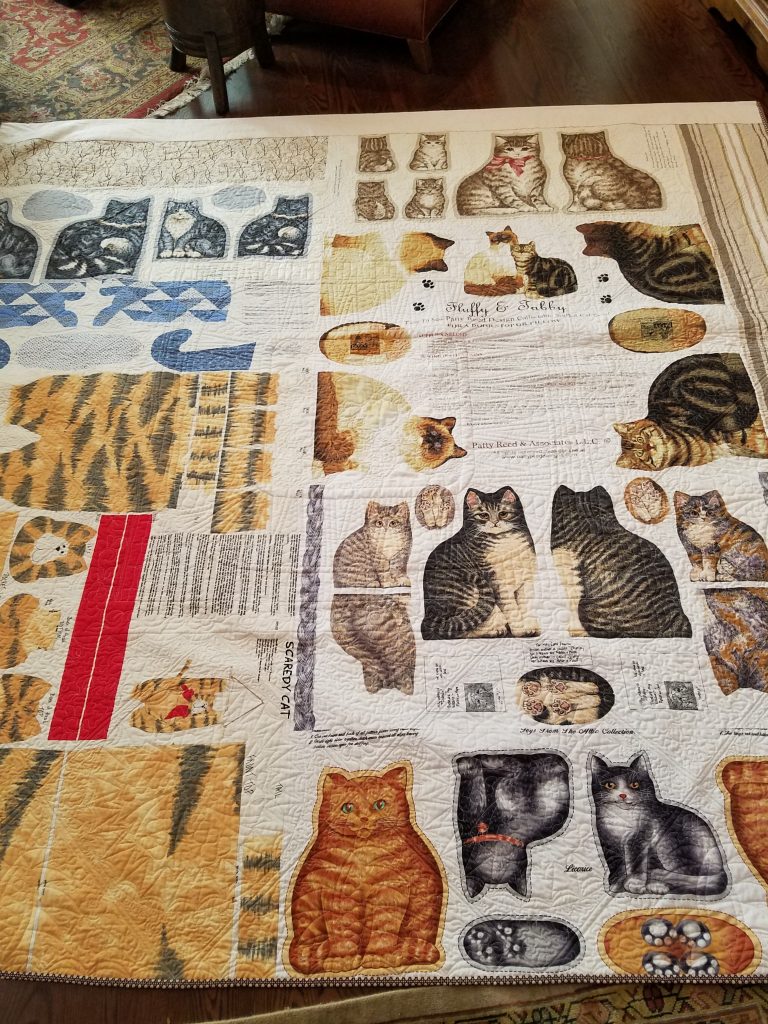

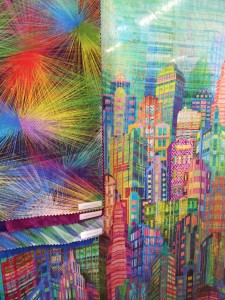

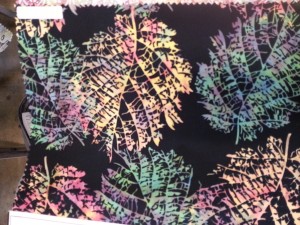

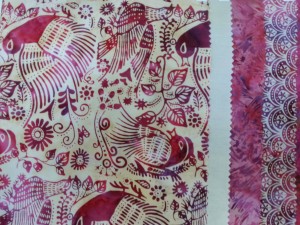

How do you organize your fabric stash? There are so many possibilities. The trick is to find a system that works for you, so that at any time you can locate the fabric that you want. Here are some ideas: by color, by project, by theme. I seem to use a whole combination of these. I like to use mono-chromatic prints, so I have piles of colors. I also have many multicolored fabrics, so there’s a stack of striped fabric and another with dots. I have floral prints, assorted animal prints, miscellaneous prints. The batiks are in a separate section, as I usually don’t mix batiks with other quilting cottons. I also have a different section for hand-dyed fabrics. Possible fabrics for my current project are strewn all over my cutting and sewing table until I’ve made my selections. They usually stay out because I never make all the decisions up front and my projects tend to evolve. Every now and then, I will stack them so that I have space to use my cutting table.

One advantage of tidying up and sorting is that you can actually see what you have. I often come across fabrics that I had forgotten that I have, and I get excited and inspired. I try to tidy up after I finish a major project, or if I’m going away for a while. If my workplace is uncluttered, it is more enjoyable being in it and I feel more creative. Most of us have more than one project going at once, so there’s usually one of two piles of projects on hold, or new ideas. My studio doubles as my office, so there are bits of paper to contend with and I’m not always very good at keeping them all organized. Once I get into a project, I like to work pretty intensively, so the room gets pretty messy. Then, I’ll get frustrated by the chaos and have a go at cleaning up. I’m fortunately to have a room to devote to my quilting and office needs. The storage places are utilized to the full, so if new stuff comes in, I really need to clear out some of the old stuff. I need to apply this principle to my clothing too….